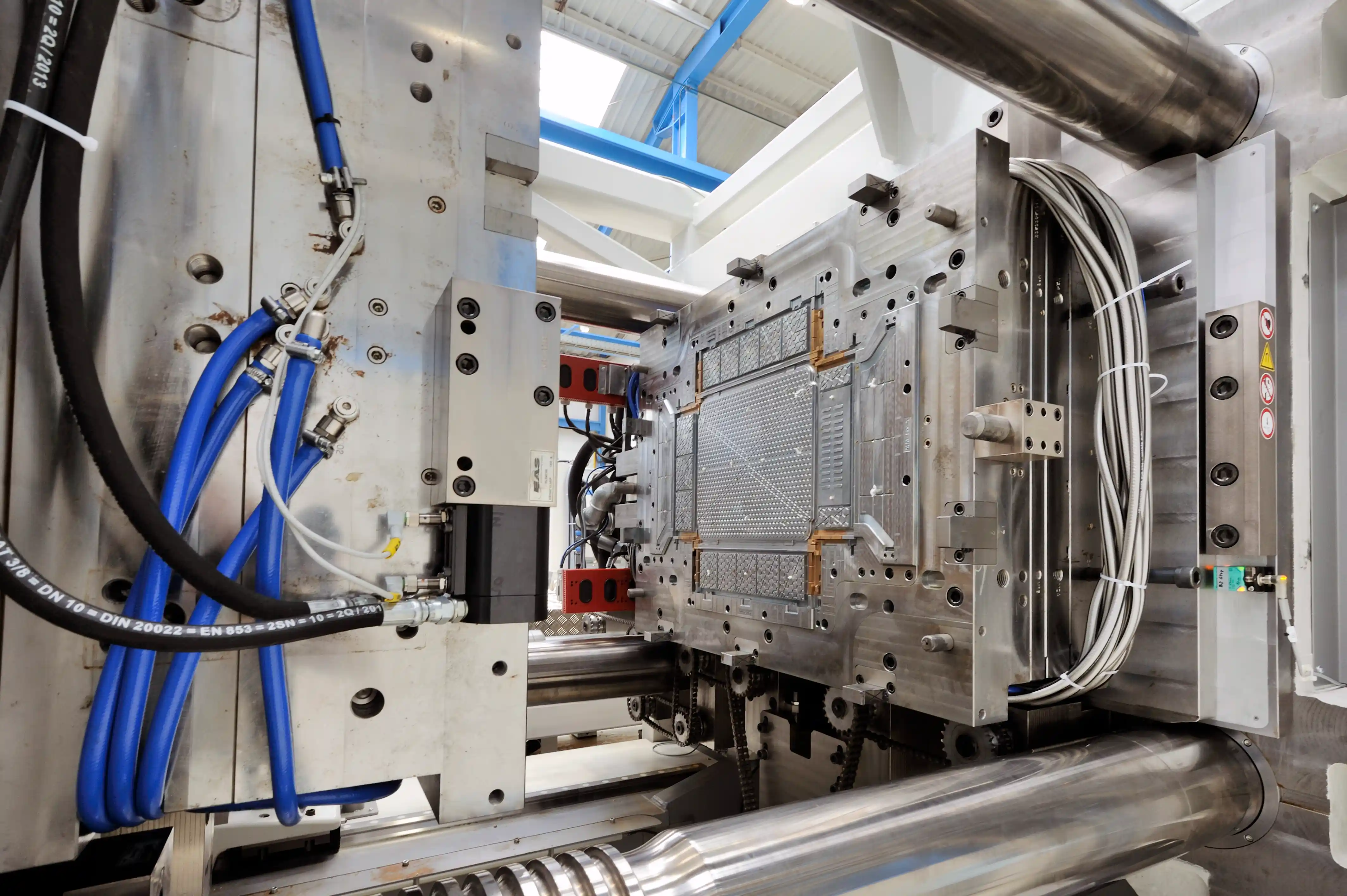

How to Design a Mold for Plastic Injection: A Professional Guide

Plastic injection mold design is one of the most important processes that has a direct influence on product quality, production efficiency, and cost. As a professional plastic injection mold factory, Wanjiada combines engineering potential with real experience to offer molds that meet our client requirements. The following is a step-by-step process of designing an efficient injection mold.

Product Analysis and Requirements

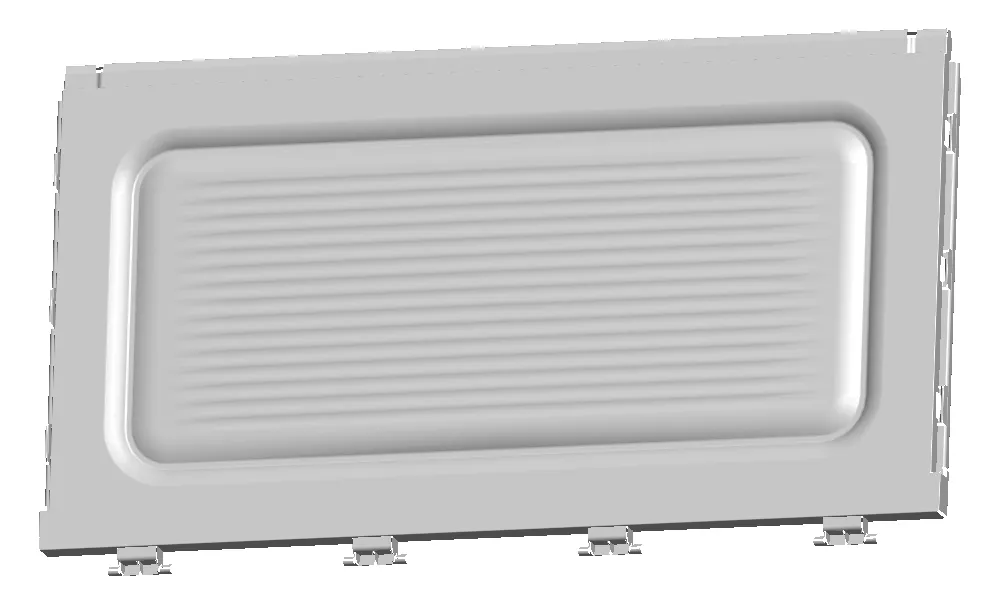

Understand the Part Design: Examine the 3D CAD model of the plastic part and determine key features (e.g., wall thickness, undercuts, ribs, and bosses).

Material Selection: Choose the right plastic resin (e.g., ABS, PP, PC) based on part function, strength, and use environment.

Surface finish and tolerances: Define the surface texture (e.g., shiny, coarse) and the dimensional tolerances to ensure that the end product meets the standards.

Determine the Mold Type and Structure

Mold Type: Decide between a two-plate mold (simpler) or a three-plate mold (complex parts with multiple gates).

Cavity Layout: Optimize the number of cavities based on production volume and part geometry. Multi-cavity molds increase efficiency but require precise balancing.

Parting Line (PL): Design the parting line to minimize flash and ensure smooth ejection. The PL location depends on part geometry and aesthetic requirements.

Gate and Runner System Design

Gate Type: Select the optimal gate (e.g., edge gate, submarine gate, hot runner) to control material flow and minimize visible marks.

Runner Layout: Design balanced runners to ensure uniform filling of all cavities. Cold runners are cost-effective, while hot runners reduce waste and cycle time.

Cooling System Design

Cooling Channels: Strategically place cooling channels near high-heat areas to ensure uniform cooling and prevent warping or sink marks.

Material Compatibility: Use corrosion-resistant materials (e.g., beryllium copper) for inserts in high-wear zones.

Ejection System Design

Ejector Pins/Blades: Position ejectors to avoid part deformation and ensure smooth release.

Draft Angles: Incorporate draft angles (1–3°) on vertical walls to facilitate ejection.

Venting and Surface Finish

Vents: Add micro-vents (0.02–0.04mm depth) to prevent air traps and burning defects.

Texture and Polish: Apply surface finishes (e.g., EDM, polishing) to meet aesthetic or functional needs.

Mold Material Selection

Choose durable materials like hardened steel (e.g., P20, H13) for high-volume production or aluminum for prototypes.

Prototyping and Testing

Trial (T0): Test the mold with short shots to validate filling, cooling, and ejection.

Adjustments: Optimize gate size, cooling rates, or venting based on trial results.

Why Choose Wanjiada for Custom Plastic Injection Molds?

At Wanjiada, we specialize in delivering high-performance, cost-effective molds tailored to your unique needs. Our advantages include:

- Expertise: 20+ years of experience in injection mold design for industries like consumer goods, toys, and packaging Industry.

- Advanced Technology: State-of-the-art CNC machining, EDM, and CMM inspection for micron-level precision.

- Rapid Prototyping: Accelerate time-to-market with quick-turnaround prototype molds.

- Cost Optimization: Design molds for longevity (500k+ cycles) while minimizing material waste and cycle time.

- End-to-End Support: From DFM analysis to post-mold services, we ensure seamless production.

Partner with Wanjiada to transform your plastic part concepts into high-quality, mass-produced realities. Contact us today to discuss your project!

Contact Wanjiada

Don't hesitate to call uswanjiada@gdboost.com

Don't hesitate to contact usWest Of The Dongsizhi Road,Jieyang Airport Economic Zone, Guangdong Province, China